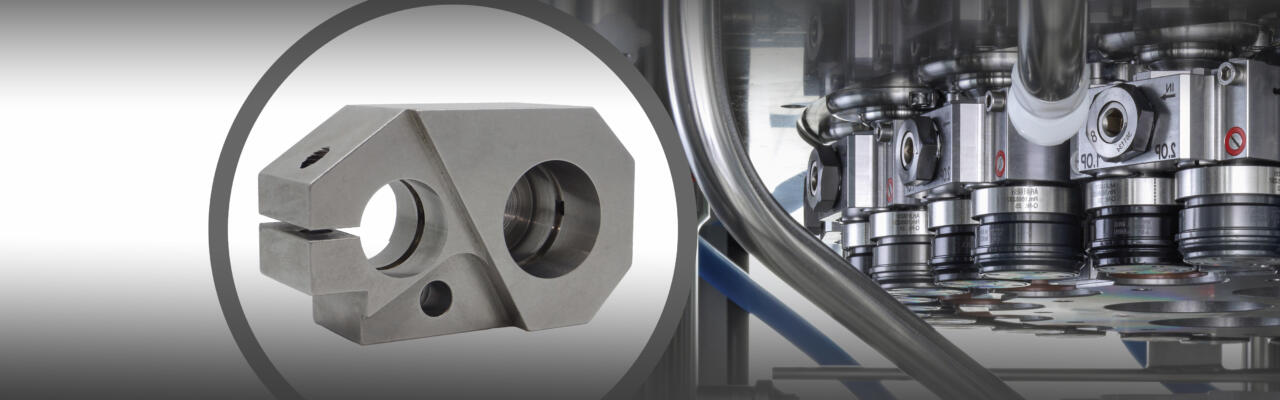

CNC-Drehteile und Frästeile als Komplettlösung

Die CNC-Drehteile und CNC-Frästeile werden einbaufertig ab unserem Lager in Thörigen an unsere Kunden geliefert. Wir bieten Ihnen eine Komplettlösung an - mehr als nur Baugruppen, Drehteile und Frästeile. CNC-Drehen ist dabei unsere Kernkopetenz.

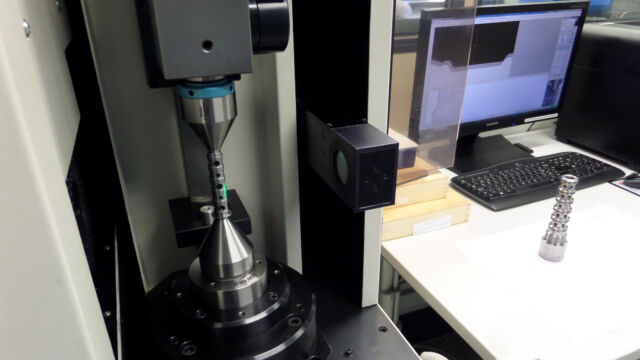

Für die Komplettfertigung einbaufertiger CNC-Drehteile und Frästeile stehen uns die hausinternen Fertigungsverfahren wie CNC-Drehen-Fräsen, Hartdrehen, Rundschleifen, spitzenloses Schleifen sowie die Montage geprüfter Baugruppen zur Verfügung. Für Oberflächenbehandlungen und thermische Behandlungen verlassen wir uns auf hochqualifizierte Partner in nächster Umgebung. CNC-Drehteile und CNC-Frästeile werden komplett einbaufertig hergestellt und für die Lieferung an Ihren Montageplatz verpackt eingelagert.